Dry ice

Definition of Dry Ice

Dry ice is a solid form carbon dioxide (CO2) gas and has a freezing temperature at -109.3° F (-78.5°C). It has an unusual property of subliming, that is transitioning from a solid to a gas, without passing through a liquid phase. Dry ice can only exist at -109.3°F or (-78.5°C) and maintains this temperature by sublimation.

How is Dry Ice made?

Liquid carbon dioxide is the source of dry ice products. Liquid dry ice is stored at 20 bar and approximately -20°C. The liquid CO2 is released thru a nozzle to 1 bar at which dry ice snow is created. The dry ice snow is compressed and extruded at approximately 1600 psi to form block or pellet form dry ice.

How do I store Dry Ice?

Store dry ice in an insulated container. Depending on the volume stored, the best container for small volume is the expanded polystyrene foam containers, and larger volumes in a rotation molded insulated filled transport container, with an insulated lid or thick quilted top pads. The thicker the insulation, the slower the rate of sublimation of dry ice (CO2) gas. DO NOT hold or store in a airtight container or sealed poly bags or glass containers. Sublimation of dry ice (CO2) gas will cause an airtight container to expand, rupture or burst. Always store dry ice in a well ventilated area. CO2 gas is heavier than air, and will drop to low areas and displace air. Consult your dry ice or CO2 gas supplier for more details, and professional advice for your specific situation.

What is the definition of sublimate?

Sublimate is the properties of going from a solid to a gas (change of state) without becoming a liquid.

Dry Ice Guide Table

How many pounds of dry ice are recommended for Frozen Packaging and Shipping

Download PDF

Dry Ice Applications

- Ship/Transport:

- Cold/Frozen Foods

- Shipping Temperature Sensitive Medical Supplies, Samples, Equipment

- Preserve:

- Seeds And Grains

- Fresh Fruits

- Fresh Meats

- Green Burials (preserves the human body)

- Flash Freeze

- Food Processing

- Processing Fresh Meat

- Processing Of Ground Meats And Sausages

- Severe weather/Power Outages

- Hunting

- Deep Sea Fishing

- Camping

- Kill Fungi And Bacteria

Dry Ice Warnings

- Dry Ice is extremely cold (-1 09.3° F, -78.5″ C) and, if not properly handled, can cause severe cold burns and frostbite.

- Do not touch Dry Ice with bare hands, use heavy insulated gloves. Rubber and plastic gloves do not provide adequate protection.

- Use protective eyewear when making or handling Dry Ice.

- Dry Ice is not edible. Do not put Dry Ice in your mouth and do not allow anyone else to do so.

- Keep Dry Ice out of the reach of children and animals.

- Do not put Dry Ice in any tightly closed container.

- Do not add Dry Ice to any liquid or any liquid to Dry Ice.

- Make and use Dry Ice only in a well-ventilated area.

- Before operating the Dry Ice Snow Maker, make sure all tank and hose connections are tight. All connections must be tightened with a wrench.

- Consult your C02 tank supplier about recommended procedures for proper tank installation, storage and operation.

ABSOLUTE-ZERO® Dry Ice Snow Maker Catalog

Is Dry Ice Safe?

- Always handle dry ice with insulated gloves as dry ice is -109.3°F (-78.5°C) and may cause cold burns if prolong skin contact.

- Dry ice is non-corrosive, non-toxic and non-conductive.

- Do not ingest dry ice.

- Do not allow unsupervised children near dry ice.

- Do not store or pack in completely airtight containers. The sublimation will cause any airtight container to expand and possibly rupture or explode.

- Intentional misuse of dry ice may be harmful or fatal. Always use extreme caution where handling dry ice.

OSHA safe levels of carbon dioxide off-gas from dry ice during vehicle transportation:

- OSHA’s maximum safe level is 3% (30,000 ppm); lethal concentration (death in 30 minutes) is 10% (100,000 ppm)

- The best way to determine the off gas is to weigh the container; for each pound of Carbon dioxide contains 8.58 cuft per lb.

- Also 3 per cent is a very unsafe level at 1.5 percent action should taken

- Suggestion is to simply put a portable Co2 monitor in the van

- 50 lb. Block contains 50 x 8.58 = 429 curt of gas, the off gassing would probably take a 7 day period

- Normal is 400 ppm in the atmosphere all the time

Dry Ice Regulating Authorities & Resources

- IATA 2018 ACCEPTANCE CHECKLIST FOR DRY ICE (Carbon Dioxide, solid)

- OSHA Carbon Dioxide in Workplace Atmospheres

- OSHA Chemical Database Carbon Dioxide

- E-CFR Title 49: Transportation PART 173—SHIPPERS—GENERAL REQUIREMENTS FOR SHIPMENTS AND PACKAGINGS, Subpart E—Non-bulk Packaging for Hazardous Materials Other Than Class 1 and Class 7, §173.217

- FedEx Packaging Perishable Shipments

- UPS Coolants and Refrigerants

- USPS Packaging Instruction 9A Dry Ice (Carbon Dioxide Solid)

-

The Sublimation Rate of Dry Ice Packaged in Commonly Used Quantities by the Air Cargo Industry

-

Hazard Associated with Sublimation of Solid Carbon Dioxide (Dry Ice) Aboard Aircraft

-

Hazardous Materials Carried by Airline Passengers and Crewmembers, 49 CFR §175.10 Illustrated

-

Is Dry Ice in your package? | US Department of Transportation

- How to Ship Dry Ice by Air with Non-Dangerous Goods

Shipping Refrigerated or Frozen Products

Every year, more products are shipped refrigerated or frozen – from cakes, pastas and ice cream to human tissues, medicines and bio-tech specimens.

The most important item needed to ship perishable products is a high-quality, industrial, styrofoam insulated cooler with a wall thickness of 1-1/2 to 3 inches. A thick-walled EPS polystyrene container will reduce the amount of cold packs or dry ice needed and extend transit times.

Choose the required shipping temperatures for your products.

DEEP LOW FROZEN use dry ice @ -108°F (-78°C).

MILD FROZEN use frozen cold packs @10°-30°F.

LOW-MILD FROZEN use frozen cold packs and a little dry ice to extend transit time by 10 up to 24 additional hours.

For products requiring a DEEP LOW FROZEN profile, general guidelines include using dry ice, approximately 5 to 10 pounds for each 24 hours of transit time. Varying quality and or larger insulated shipping containers will require more dry ice to cover larger surface area. Load dry ice on bottom of container, then load products to ship and cover with dry ice. Dry ice will freeze and keep product frozen. For the required amount of days to ship, multiply the dry ice per each 24 hours of transit. Fill all void areas remaining inside insulated container with solid dunnage packaging material. This improves temperature stability and reduces dry ice sublimation.

For products requiring a MILD FROZEN profile, general guidelines for maximum product protection include: Surround product on 2 or 4 sides and on top and bottom. Varying quality and/or larger insulated containers including larger product pay load will require larger and more cold packs for the number of

days in transit. General ratio to start is 1 lb. cold pack per 3 lb. of product and may require more. Fill all void areas remaining inside insulated container with solid dunnage packing material, this improves temperature stability.

For products requiring a LOW-MILD FROZEN profile, general guidelines for extended transit from 10 to 24 additional hours and lower frozen profile include: Surround packed product with frozen cold packs on 2 or 4 sides and place on top and bottom. Varying quality and or larger sized insulated containers and larger payload of product will require larger and possible additional cold packs to accommodate for extended transit time. Fill all void areas remaining inside insulated container with solid dunnage packaging material, place from 1-1/2 lbs. to 5 lbs. of dry ice on top of cold packs and packaging filler to buffer from packed product. This will enhance temperature and transit an additional 10 to 24 hours.

* Warning – Certain temperature sensitive items may be exposed to heat loss and freezing may result. Vaccines not recommended.

Contact parcel shipper for the correct labeling instructions and documents to declare weight and dry ice used in each package.

Always be sure work areas and transport vehicles are well ventilated when working with or transporting dry ice and packages with dry ice. Consult your local dry ice and liquid CO2 supplier for more information.

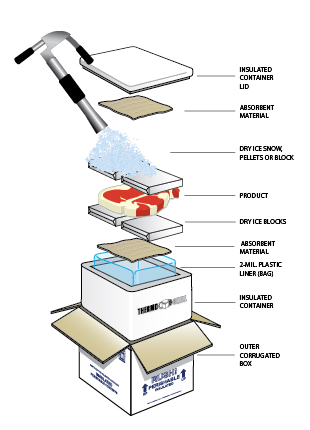

Packaging Using Dry Ice

- Line the insulated container with at least one 2-mil. plastic bag and sufficient absorbent material above and below the product.

- Double bag products that can thaw or melt.

- Arrange products compactly. Leave space around product for dry ice. Close bag securely.

- Place sufficient amount of dry ice around product. Use dry ice block, pellets or snow.

- Pack tightly and fill void spaces with dunnage packaging material to prevent product movement.

- Place lid on insulated container. DO NOT seal completely – venting is needed to allow carbon dioxide gas to escape.

- Place insulated container inside corrugated box.

- Securely tape corrugated box with plastic carton sealing tape. Complete the required paperwork and labeling.

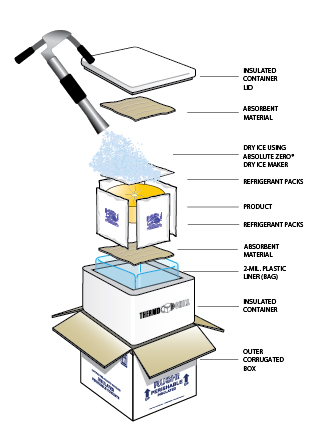

Packaging Using Cold Packs and Dry Ice

Package conditioning for perishable product shipment, extended 10-20 transit hours

- Line the insulated container with at least one 2-mil. plastic bag and sufficient absorbent material above and below the product.

- Arrange products compactly, allowing space for cold packs.

- Place sufficient number of cold packs on top and around product. Pack tightly and fill void spaces with dunnage packaging material to prevent product movement.

- Fold or close the liner.

- Apply 1 to 1-1/2 pounds of dry ice snow above secured liner.

- Place lid on insulated container. DO NOT seal completely – venting is needed to allow carbon dioxide gas to escape.

- Place container inside corrugated box.

- Securely tape corrugated box with plastic carton sealing tape.